Test and tagging is a generic name given to the process of visually inspecting and electrically testing in-service electrical equipment for personal safety. Colloquially, it is also referred to as; tagging, test tag, test and tag, electrical tagging, appliance testing, portable appliance test or lead tagging.

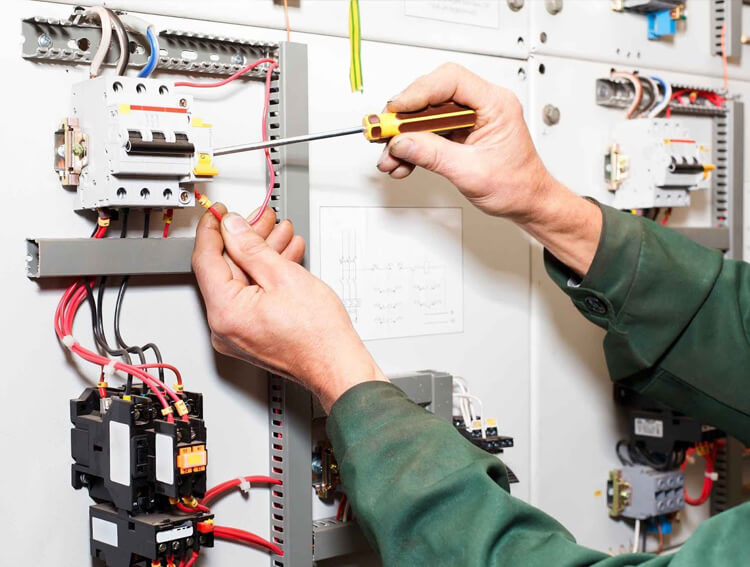

The aim of test and tagging is to determine if the appliance is electrically safe for personal use. The appliance undergoes a visual inspection for defects such as damage or missing components and a number of electrical tests to measure earth continuity, insulation resistance and polarity.

In Australia and New Zealand, this is done using the Standard; AS/NZS 3760:2010

In-service inspection and testing of electrical equipment” as a reference document.

Electrical safety and regular yearly inspections of your electrical tools, appliances, power leads, extension leads and all other workplace and home electrical equipment are not to be taken lightly.

Each year in New Zealand there are dozens of workplace related deaths caused by electrocution and many more serious injuries or destructive fires. The more shocking stats are for the home. Most of these could have been prevented with regular Test and Tag inspections.

This is why it is now WH&S legislation that some businesses, contractors, sole traders operating in a working environment must have a regular test and tag performed on their electrical equipment if they want to be compliant with the AS/NZS 3760:2010.

Workplace Safety

If you are an employer, you have a duty of care to ensure that employees and visitors to the workplace are safe from injury and risks to health. You must therefore manage any safety risks surrounding electrical hazards, in accordance with the requirements of the AS/NZS 3760:2010.

You must apply a systematic risk management approach to eliminate or control the risk of electrical hazards. After the risk assessment, you can then implement a range of control measures including:

- Routine Visual Checks

- Regular Inspection

- Maintenance

- Repair

- Replacement

- Use Of Residual Current Devices (RCDS)

- And, Where Warranted, Testing Of Identified Electrical Equipment.

Service Packages

V x 10

- Testing of Electrical

Devices: 10 - Location: Your Home, Office, Worksite, Workplace

- Price: $50 + GST

V x 100

- Testing of Electrical

Devices: 100 - Location: Your Home, Office, Worksite, Workplace

- Price: $3.95 + GST / Item

V x 1000

- Testing of Electrical

Devices: 1000 - Location: Your Home, Office, Worksite, Workplace

- Price: $2.95 + GST / Item

Our Test and Tag trained operator will perform the following on each appliance:

- Each appliance will be disconnected from the power and visually inspected for any damage or wear. This includes the plug-in, damage to the cord insulation, flexibility for the cord and anchors.

- The Vani Limited Test and Tag Technician will use our state-of-the-art instruments to test for dangers that cannot be seen by the human eye like damage to the insulation or bad earth.

- Once the device is passed it will have a Vani Limited Test and Tag sticker put on it which will indicate the date, time, and operator that tested it.

Is your microwave safe to use?

- Microwave ovens are used daily in restaurants, cafeterias, lounges, kitchens, snack bars, and homes. Microwave oven users are often concerned about potential health hazards from exposure to microwave radiation leakage.

- Microwaves can start to leak dangerous radiation that can be extremely harmful and, in some cases, deadly. Our trained professional operator can test this for you for just $29.95

FOR A PROMPT PROFESSIONAL & FRIENDLY SERVICE GUARANTEED

Subscribe for our News Letter

Subscribe for our News Letter keep in touch with our industry. Your Information is safe with us. We also hate spam as you.